Developing a medical device is more than just an engineering challenge—it’s a transformative process that directly impacts patient care and business success. For healthcare professionals and organizations invested in advancing medical solutions, understanding the intricacies of device engineering is vital. From ideation to commercialization, medical device development demands precision, innovation, and a commitment to quality. The global medical device market, valued at $495 billion in 2022, is projected to exceed $750 billion by 2030, fueled by advancements in technology and the growing demand for patient-centered solutions.

If you’re in the healthcare field, partnering with experienced engineers can streamline the process, ensuring that your medical devices meet rigorous regulatory standards while exceeding patient and provider expectations.

What Is Medical Device Engineering?

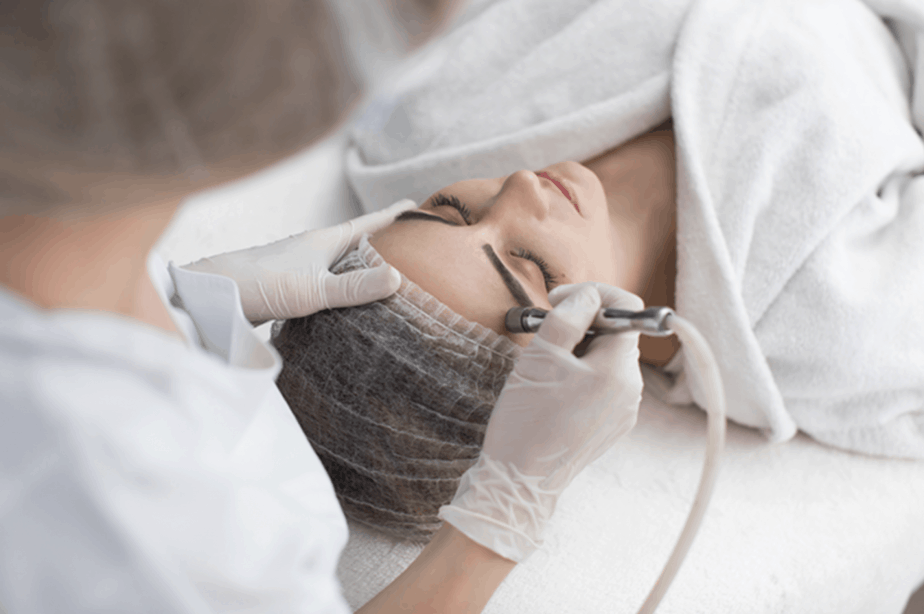

Medical device engineering involves the design, development, testing, and manufacturing of tools and systems that improve healthcare outcomes. These devices range from basic tools like walkers to advanced diagnostic systems such as MRI machines and wearable technologies.

For instance, wearable glucose monitors, which are becoming essential for diabetes management, have driven a 15% increase in the wearable medical device market annually. Similarly, advancements in imaging tools have improved diagnostic accuracy for conditions such as cancer and cardiovascular diseases, enhancing both speed and reliability.

At the heart of this process are multidisciplinary teams of bioengineers, software developers, and industrial designers who work collaboratively to create devices that are not only functional but also intuitive and safe for users.

The Importance of Medical Device Engineering

Medical devices are not just products—they are lifelines that enhance patient care and improve workflows for healthcare providers. A poorly designed device can fail to meet regulatory standards or alienate users, whereas well-engineered devices can revolutionize treatment protocols and drive market success.

Transforming Patient Care

Devices like portable ultrasound machines and robotic surgical systems have improved accessibility and precision, reducing recovery times and improving outcomes. Robotic surgery tools alone have decreased surgical error rates by 65%, demonstrating the transformative potential of innovative engineering.

Supporting Healthcare Providers

By addressing the real-world needs of patients and providers, engineers create tools that streamline operations, reduce cognitive load, and ensure safer interventions. This collaboration often results in solutions that are intuitive, reliable, and adaptable.

Steps in Medical Device Development

The path from concept to commercialization involves several critical phases:

1. Concept Development

The process begins with understanding market needs and brainstorming ideas. For example, a team developing a portable dialysis machine might engage with patients and providers to identify pain points. Rapid prototyping and iterative feedback allow for the testing of initial concepts, ensuring alignment with user expectations.

2. Engineering and Refinement

In this phase, engineers refine the design based on initial feedback, developing detailed specifications and performing hazard analyses. With global regulatory standards in mind, teams ensure that the device meets both functional and safety requirements.

3. Verification and Validation

Rigorous testing ensures that the device performs as intended under various conditions. For instance, wearable devices are tested for both durability and accuracy during extended use. Verification ensures adherence to design goals, while validation confirms usability in real-world scenarios.

4. Manufacturing Scale-Up

Scaling up involves validating production processes, qualifying suppliers, and meeting sterility and shelf-life requirements. By the end of this phase, the device is ready for full-scale manufacturing, complete with regulatory approvals and market-ready packaging.

5. Full-Scale Manufacturing

Once all approvals are in place, the device enters full production. Teams focus on efficiency and quality, ensuring that the product meets demand while adhering to strict compliance standards.

The Role of Technology in Medical Device Engineering

The integration of cutting-edge technologies like AI and virtual reality is reshaping the medical device landscape. AI-powered diagnostic tools, for instance, are reducing the time to detect conditions by 30%, while virtual reality is enhancing surgeon training and patient rehabilitation.

Furthermore, advanced manufacturing techniques such as additive manufacturing (3D printing) enable rapid prototyping and customization, reducing development time by up to 50% compared to traditional methods.

Real-World Impact

Consider the development of an innovative wearable cardiac monitor. By collaborating with a multidisciplinary engineering team, the device was brought to market in under two years—40% faster than the industry average. The monitor’s intuitive design and real-time data capabilities have since improved patient compliance and provided physicians with actionable insights, illustrating the profound impact of thoughtful engineering.

Partnering for Success

Whether you’re an established healthcare organization or a startup with a breakthrough idea, selecting the right partner for medical device engineering can determine your success. Companies like Gener8 provide end-to-end engineering services, from concept development to full-scale manufacturing, ensuring a seamless transition through every phase of the development process.

Key Benefits of Partnering with Experts:

- Accelerated Time to Market: Experienced engineers refine designs for manufacturability, reducing delays and ensuring efficient production.

- Reduced Costs: Design-for-manufacturability techniques lower production costs by minimizing complexity and improving scalability.

- Regulatory Expertise: Navigating global compliance standards with ease ensures a smoother path to market.

Conclusion

Medical device engineering is not just about creating tools; it’s about delivering solutions that transform healthcare. From improving patient outcomes to supporting providers with reliable technology, every step in the engineering process is an opportunity to make a meaningful impact.

For healthcare professionals, collaborating with expert engineers ensures that your devices meet the highest standards of quality and innovation. As the medical device market continues to expand, investing in robust engineering and development processes is essential for staying ahead in this competitive field. Together, we can shape the future of healthcare—one device at a time.

Follow Us